BRAKING NEWS FOR THE SHIPPING INDUSTRY

This kind of growth is a common problem and a real nightmare for both the chief and the skipper.

An ANODE helps protect metal underwater from electrolytic corrosion.

An ULTRASOUND transducer controls biofilm, bacteria, and growth!

Fouling will result in engine overheating and substantial costs!

Biofil are formed by the unwanted settlement of single and multicellular organisms on liquid carrying surfaces. Initially, dissolved organic molecules are adsorbed onto any submerged material, held namely by the van der Waals forces. Then, bacterial and algal cells adhere to the surface, mediated by secretion of glue – like substance of extracellular polymers or EPS, which contain polysaccharides, proteins and nucleic acids. As the biofilm matures, it starts to disperse and spread over a larger area. It also hardens, which increases its mechanical resistance. The formed community secretes a number of chemical cues that attract bigger, often sessile organisms, like mussels and barnacles on various locations such as hulls, seawater cooling systems, propellers, tanks and freshwater generators. In industrial plants, biofilm favors the deposition of organic and inorganic residues, which leads to accelerated corrosion. In industrial and shipping cooling systems, biofilm hosts bacteria species such as

Legionella or Pseudomonas.

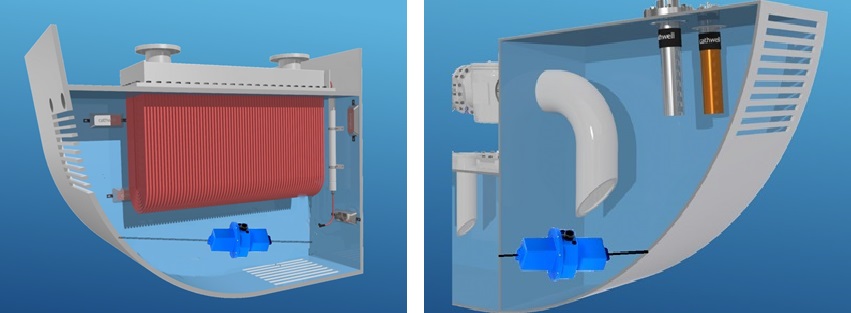

QUATTROBLU ultrasound system for Sea Chest.

Since our first 2016 release, our ALPHA QUATTRO systems have available

more discrete frequencies and bandwidths than all competitor’s combined!

The whole package includes

Manual book

4-ways transducer

30m transducer cable

316 stainless steel chains

Bluetooth communication is built in

Universal 85Volt to 240Volt (50/60Hz)

Variety of international adapters Included

Hardwired to your exiting 24Volt/dc power supply

These are the reasons why the company should invest in the latest ultrasound technology

to proactively prevent fouling, rather than incurring unnecessary problems and significant costs to repair the damage.

Causes of Engine Overheating

Common causes of engine overheating on large ships include:

- Insufficient Coolant Levels: Leaks or malfunctioning pumps can cause a drop in coolant levels, leading to inadequate heat dissipation.

- Clogged Coolers: Saltwater and debris can block the cooling system, reducing the effectiveness of heat exchange.

- Faulty Thermostats or Sensors: If the temperature control systems malfunction, they may fail to regulate engine temperature properly.

- Inadequate Ventilation: Blockages in air intakes or malfunctioning fans can prevent the engine from cooling properly.

- Overload or Poor Maintenance: Running the engine under heavy load or failing to maintain it properly can lead to overheating.

THE PROBLEM NOBODY TALKS ABOUT

Anti-corrosion coatings don’t last long and are often washed or scraped off when divers are cleaning.

Biofilm then takes over and forms colonies inside the pipes. This “carpet” of unwanted biological organisms,

such as seaweed, algae, and bacteria, restricts the flow and, in turn, lowers the thermal performance of the cooler–

which affects all the equipment connected to the box coolers.

Ultrasound controls biofilm and bacteria. Without biofilm and bacteria, no growth occurs.

Without sufficient cooling, a common consequence is that the ship must reduce its speed, leading to major financial consequences

HOW ULTRASOUND WORKS

The ultrasonic sound waves emitted by the hull or structure create microscopic cavitation bubbles environment. These bubbles

cause a very unique environment close to the hull or structure, the tiny bubbles burst, split single-cell micro-organisms such

as algae sidewall. This cavitation has a cleaning action helps to maintain the benefits of hull cleaning. The initial removal of

algae growth inhibition food chain barnacles and other marine life feeds algae, efficiently generating an environment

habitable by the algae and barnacles grow further.

HALPHA BLU

ALPHA BLU is a onetime low-cost investment designed to reduce the number of dry dockings needed over the years.

The unit is extremely durable and adaptable so that it can be positioned on the jetty in a front of the vessel. Your “neighbors”

will be more than happy as well, because boats hull around you will also remain clean and always looking well maintained.

Your boat will keep its speed and fuel efficiency year after year! On top of all of this almost maintenance free. Just clean

the transducer with a smooth cloth ones every 4-5 weeks.

ADVANTAGES OF ULTRASOUND AND MODEL BLU

1 One time investment!

2 Kills existing barnacles and shells over a short period of time!

3 Prevents new barnacle and shell growth!

4 Achieves massive cost savings to your maintenance budget!

5 Model BLU is useful wherever there are fouling problems!

6 Installation with and without dry docking!

7 Consistent travel speeds between dockings!

8 No more fouling problems with the cooling systems!

9 Tested for over 10 years with amazing results!

10 Cheapest way of antifouling- ever!

11 Save on downtime!

12 No installation

13 No maintenance!

14 The system is flexible!

15 Model ALPHA BLU is 100% environmentally friendly!

16 THIS system will NOT affect other electronics onboard the boat.

17 TOP quality USA product.

18 NO drilling!

10 IT WORKS!

Ultrasound is the premium system for clean sea chest, box coolers, strainers,

hull and freshwater tanks and replace expensive and dangerous chemicals.

HUGE money saver and 100% environmentally friendly and no maintenance.

ONE time investment!

ULTRASONIC BALLAST WATER DISINFECTION

The ultrasonic treatment system has demonstrated to be effective in the killing of bacteria, plankton, and larger organisms.

The ultrasonic disinfection of ballast water is a mechanical/ physical treatment, which avoids the dosing of any strong

and expensive active chemicals into the ballast water. This ensures an ideal environmental acceptability combined with high

biological effectiveness regarding the destruction and inactivation of plant and animal organisms and microorganisms in the ballast water tank.

Read more:

https://www.hielscher.com/ultrasonic-ballast-water-disinfection.htm

Some of our shipping customers:

Ultrasound is for shipping companies who consider economics, health, environment and safety.

ALPHA system keeps freshwater tanks clean for bio film, bacteria and growth.

Without chemicals in the water and no chemicals for cleaning, it gives a huge financial saving.

ULTRASOUND SOLVES MANY PROBLEMS ON BOARD

AND ALPHA mod. Quattro-DB® 4-ways IS THE SOLUTION!

Scientifically proven technology,

Ultrasonic control of algae is a documented method. Ultrasonic processing is used in many industries and has long been

known to destroy bacteria and algae on a molecular level. This has been tested by many universities

and research institutes around the world (including thoroughly tested and proven by the Australian Navy).

ALPHA technology brings this ultrasound solution for a reliable, secure, power conscious and

very effective system with many years of experience that is required to use the solution effectively for water treatment.

UNWANTED MUSSEL FOULING

Mussels live mainly off algae in the sea water, and this is where the problems begin with the mussels clogging our systems.

This in turn leads to the higher temperatures in the cooling of water. Businesses that use sea water for cooling

have two solutions, chemicals and cleaning. It turns out that the mussels have become so clever that when the chemicals

get into the water system they close themselves in order to survive.

The mussels main consumption are microscopic algae and phytoplankton, but they will also be able to make use of other

organic particles such as bacteria and detritus. Mussels live by filtering out and eating small, organic particles from the sea.

The main food for the mussels is freely floating microscopic algae called the plant plankton or algae-plankton. The presence

of toxic algae plankton mussels will accumulate from these toxins. The amount of toxic algae present says something about

the risk that mussels can accumulate algae-toxins to levels that make them unfit for consumption.

Ultrasonic benefits

associated with algae and bio fouling in Marine systems including.

- Reduced maintenance requirements

- Extended Haul Out and Anti-Fouling intervals

- Improved Performance

- Reduced Fuel Consumption through reduced drag

- No Consumables (no electrodes to replace)

- Maintains submerged structures.

- Destroys Algae & halts mussel growth lifecycle.